Subway Lift

In 2011, Handi-Lift partnered with Subway and Tishman to install an award-winning, keyless vertical platform lift in a New York City subway station, setting a new standard for accessibility and earning Elevator World Magazine’s Wheelchair Lift Project of the Year.

Unlock exclusive access to comprehensive solutions library and get access to the over 300+ projects

Overview

In 2011, Handi-Lift designed and installed the first keyless vertical platform lift in an active New York City subway station, a groundbreaking project that set a new standard for accessibility in one of the most demanding environments in the world. This innovative lift, installed at the Hotel Intercontinental site in collaboration with developers Tishman, addressed complex site constraints while meeting the rigorous requirements of the MTA. The project earned Handi-Lift Elevator World Magazine’s Wheelchair Lift Project of the Year award.

Challenge

The challenge was to build a lift that would be servicable in the demanding environment of an active subway station.

The project faced unique and demanding challenges:

Harsh Environment: The lift needed to withstand the NYC subway’s metal dust, frequent power washing, and 24/7 usage.

Stringent MTA Standards: The MTA required a “bulletproof” design that exceeded standard safety and serviceability expectations for accessibility equipment.

- Site Constraints:

Limited overhead clearance and maneuvering space.

A shallow 2” pit and underlying sewer line at the intermediate landing.

Structural considerations related to the sidewalk and subway tracks.

Precision Requirements: The lift’s dimensions had to be accurate to within ¼” before final field measurements were possible, requiring meticulous planning and coordination.

Design & Execution

- Innovative Two-Lift Solution:

A commercial-grade elevator transported passengers to an intermediate landing.

Handi-Lift’s custom wheelchair lift provided accessibility from the landing to the track level.

- Custom Drive System:

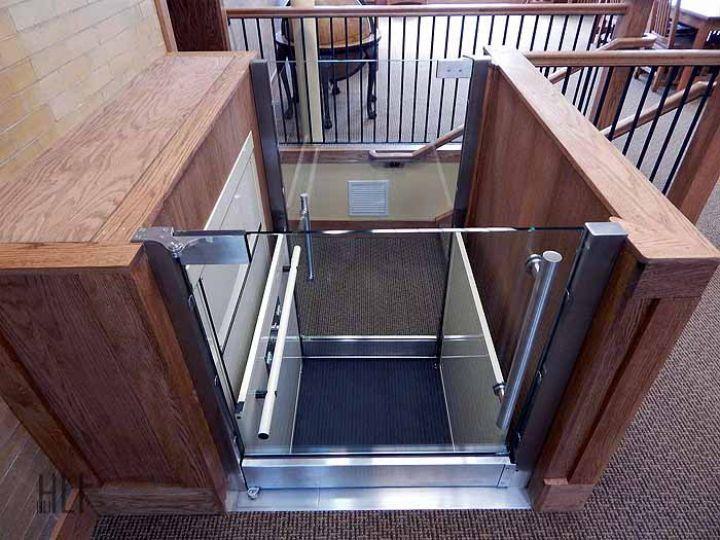

Lift‑U developed a cantilevered twin-screw direct drive system, customized for the project, capable of enduring the subway’s harsh conditions.

The system was tested for 10,000 cycles under full load before installation.

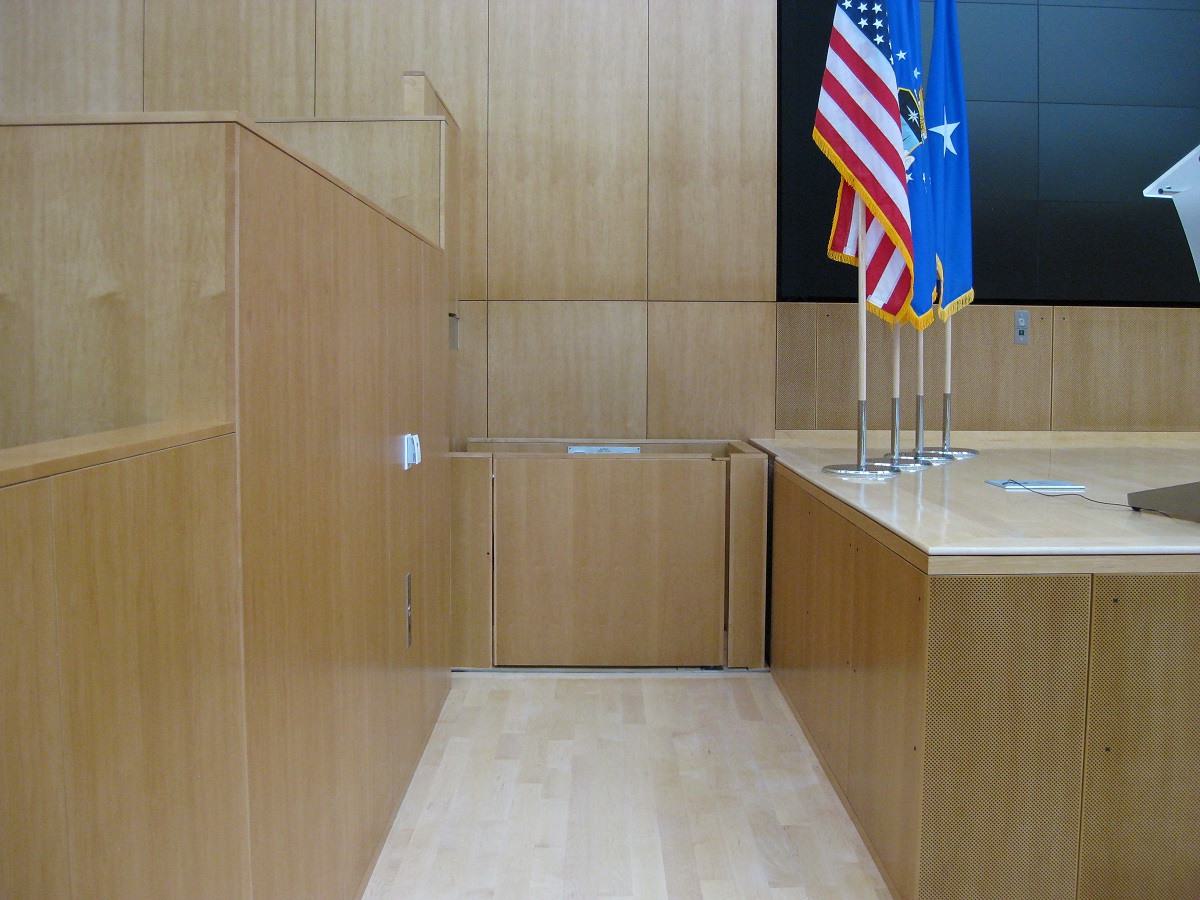

- High-Quality Enclosure:

The stainless steel and glass enclosure was fabricated by INA Building Shop and InDetail.

The entire system was mocked up off-site to ensure precision before installation.

Field Adjustments: Despite a 1” discrepancy in the finished floor height, the team made on-site adjustments without needing to return the lift to the factory, keeping the project on track.

Results

The project successfully delivered an accessible solution that met the MTA’s high expectations and overcame the complexities of an active subway station environment.

Award-Winning Innovation: Handi-Lift’s efforts were recognized with Elevator World Magazine’s 2011 Wheelchair Lift Project of the Year award.

Enhanced Accessibility: The custom lift provides reliable, round-the-clock service in a challenging environment, ensuring accessibility for passengers with mobility challenges.

Proven Durability: The lift’s robust design and innovative engineering established a new benchmark for future subway accessibility projects.

Award Winner!

2011 Wheelchair Lift Project of the Year

Elevator World Magazine

Download the PDF | Read More

Technical Specifications

-

Quick Stats

Name Value Travel 51.5 inches Speed c.10fpm Capacity 750lbs. Configuration Two stops, straight through. -

Enclosure

The enclosure frames are 2” stainless tubing with channels for ½” safety glass. The glass is set inside the frames to avoid interior pinch points (as required by code). The glass can be removed from the outside if it ever needs to be replaced. The MTA also specified anti-graffiti film on both sides of all glass panels.

-

Electrical

The motor, controller, and UPS back up system are hidden underneath the upper landing sill. The ¾” thick aluminum platform is structural — the drive system picks the lift up from the car sides. This means we could install this heavy duty lift in only a 2” slab depression.

All electrical connections (to the remote hall stations, the phone line, the MTA LiftNet monitoring system, the electrical power source, etc.) had to be in conduits laid in before the concrete was poured and so all electrical connections terminate in the space under the upper landing, hidden from view. Service requires removal of the stainless panel under the upper landing from inside the car (or under the car if in the upper landing position).

The disconnect (AC/DC) for the power source is located with battery back up system. The disconnect for the power door operators, along with a GFI outlet, are in an access panel at the upper landing for ease of access and service.

-

Drive

The drive motor is 2HP, totally enclosed non-ventilated (TENV), 3 phase. The control system is a variable frequency drive with a programmable logic controller.

The MTA approved the Lift-U direct drive system because it does not use hydraulics, which the MTA efforts to avoid even in commercial elevators.

-

Special Features

The ADA phone was a T1250 by VPP (Vandalism Proof Products) distributed by Janus

The power door operators are by Tormax. We wanted to use their TN series but there was no way to get the pocket in the floor at the upper landing over the lift mechanism or below due to limited pit depth so we went with their low energy TTXII overhead operators.

Location

392 West 44th Street, New York, NY