United States Air Force Academy

The first major building erected on the Air Force Academy campus since the iconic Chapel was completed in 1963 is the brand new Center for Character and leadership Development (CCLD). This new building was designed by SOM New York Office. SOM was the firm that designed the original campus which has become a national historic district.

Unlock exclusive access to comprehensive solutions library and get access to the over 300+ projects

Overview

The Center for Character and Leadership Development (CCLD), also known as Polaris Hall, is the first major building to be erected on the Air Force Academy campus since the completion of the iconic Chapel in 1963. Designed by SOM’s New York Office, the CCLD reflects the architectural legacy of the original campus, which is recognized as a national historic district. A signature feature of the building is its tower, canted at a 39-degree angle to align with Polaris (the North Star), symbolizing the academy’s unchanging core values. The building serves as a hub for leadership development, hosting events, meetings, and honor board hearings.

Challenge

The CCLD presented several challenges during its design and construction:

Symbolic and Functional Design: The tower’s alignment with Polaris required collaboration with astronomer Dr. Devin Della-Rose to ensure the North Star remained due north at a 39° altitude. This alignment held symbolic and architectural significance, as seen from the Honor Board Room.

Accessibility Issues: The sunken forum, located beneath the skylight and serving as the main gathering space, spans three levels: the grade-level office floor, the stage, and the forum floor. Ensuring seamless accessibility between these levels posed a significant design challenge.

Construction Delays: The project faced numerous delays, including a pipe break just before the scheduled opening.

Design & Execution

Handi-Lift, Inc. was first consulted on the design of the accessibility lift in 2011. Over the course of the project:

Customized Accessibility Solution: Handi-Lift provided input to address the forum’s multi-level access requirements, ensuring that all three levels—the office entry, stage, and forum floor—were interconnected through an accessible lift solution.

Collaborative Approach: The lift design was integrated into the building’s architecture, complementing the innovative and symbolic features of Polaris Hall while adhering to accessibility standards.

Overcoming Delays: Despite multiple delays, including last-minute construction challenges like the pipe break, the team persevered to ensure the building’s completion.

Results

The CCLD was completed in April 2016, delivering a functional and symbolically rich addition to the Air Force Academy campus.

Impactful Design: The alignment with Polaris serves as a constant reminder of the academy’s core values, visible from the Honor Board Room and integrated into the forum’s architectural elements.

Accessible Space: The forum and its three levels were made fully accessible, reflecting a commitment to inclusivity.

New Campus Landmark: Polaris Hall stands as a modern testament to the values and vision of the Air Force Academy, blending accessibility with architectural innovation.

Technical Specifications

-

Travel Distance

The lift was designed to serve three levels with a travel distance of only 69”.

-

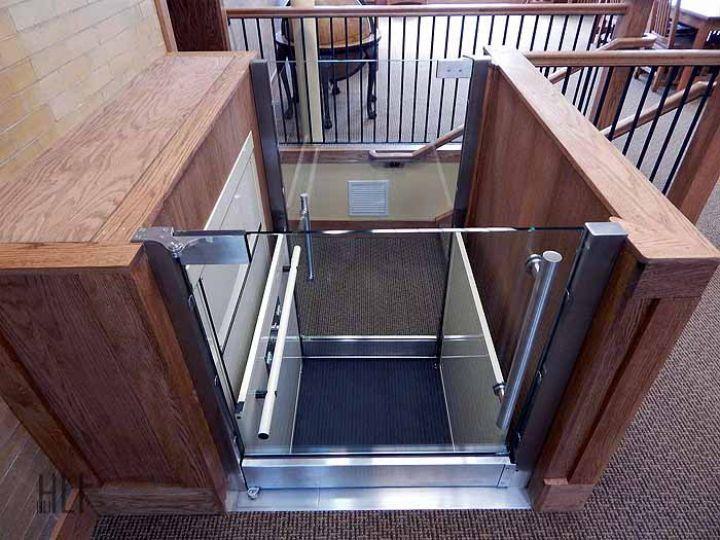

Platform Entrances

Three entrances were required on three of the four sides of the platform to accommodate access at different levels.

-

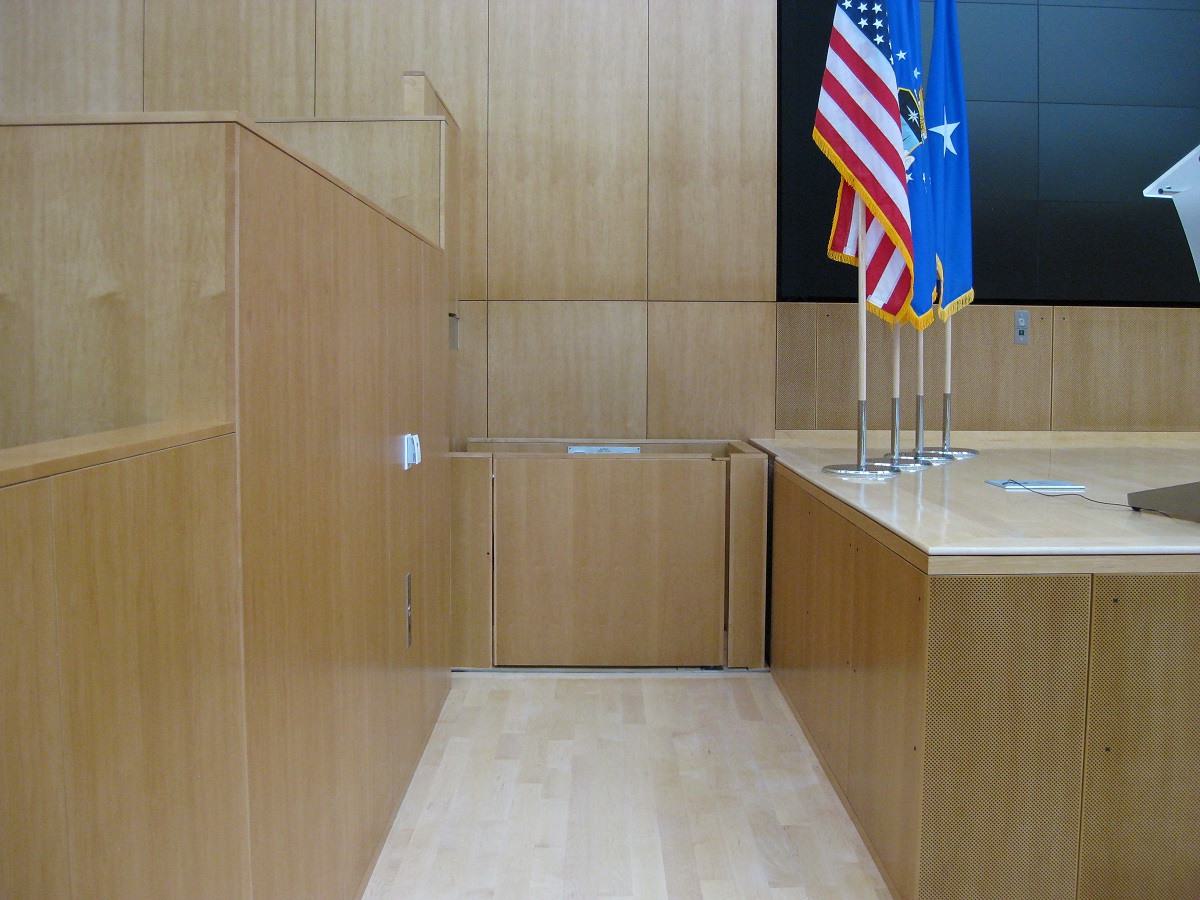

Stage-Level Integration

The lift does not project above the stage level when not in use and is covered in millwork to match the surroundings.

-

Enclosure Configuration

Designed as a Partial Enclosure per ASME A18.1 rules, incorporating a “ToeGuard” skirt system underneath the lift and automated gates.

-

Automated Gates

All three gates were automated to meet ANSI A117.1 standards, using Tormax in-floor operators for aesthetic and functional requirements.

-

Gate Mechanism

- Upper landing gate integrated with the balustrade.

- Platform gates were center-hung with reversed swing-out rotation.

- Gates incorporated a false floor 8” thick, including 1” wood flooring, to accommodate the operators.

-

Drive System

- Lever hydraulic drive system by Autoquip, modified for a 2,500-pound capacity and customized hydraulics and controls.

- Double table configuration to achieve the necessary travel.

-

Skirt Design

A telescopic skirt system was implemented to protect the underside of the lift at upper and middle landings due to limited pit depth.

-

Pit Depth

The lift required a pit depth of 7’0” but only 3’0” was available, necessitating the use of a telescopic skirt and careful trade coordination.

-

Material Construction

- Platform gates and side barriers were fabricated with heavy steel to accommodate ½” millwork on all sides.

- Custom fabrication by Pabst Enterprises, including the telescopic skirt.

-

Millwork Integration

Millwork was provided by ISEC, including precise cutouts for gate pivots and interlocks.

-

Fixtures and Interlocks

- Fixtures on each landing and the platform were supplied by EPCO.

- Interlocks were Garaventa PL2000.

-

Equipment Placement

Pump, controller, and gate operator controllers were installed behind removable panels at the upper landing, requiring extensive trade coordination.

Location

Colorado Springs, CO