Bank of America Building

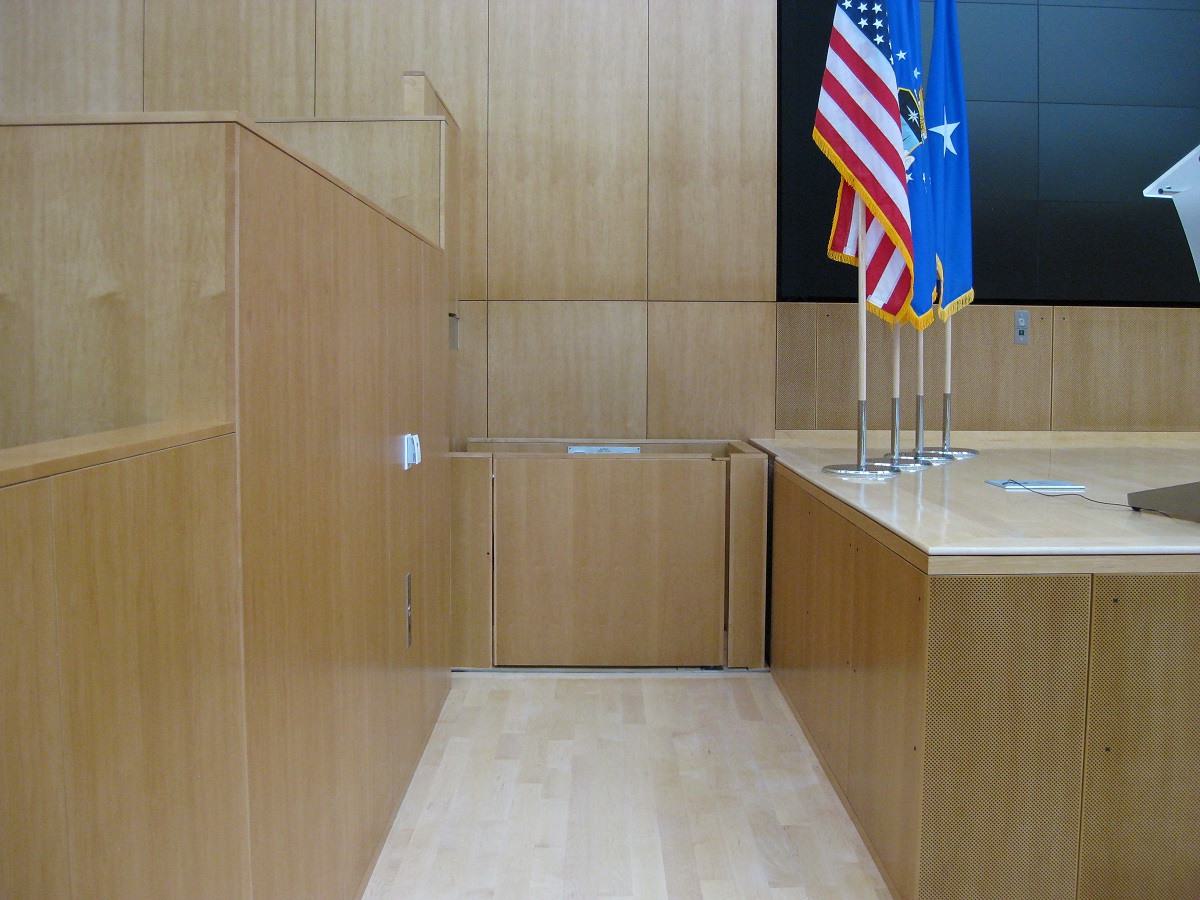

Handi-Lift designed and installed a custom vertical platform lift for the Bank of America Tower, providing seamless accessibility between the office lobby and flagship branch while aligning with the building’s modern aesthetic.

Unlock exclusive access to comprehensive solutions library and get access to the over 300+ projects

Overview

The Bank of America Tower, housing both the company’s headquarters and flagship branch, serves as a showcase of cutting-edge technology, interior design, and innovation. A custom vertical platform wheelchair lift, designed and built by Handi-Lift, provides accessibility between the office lobby and the branch, ensuring convenience for VIPs, corporate clients, and partners touring the space. The project required a solution that aligned with the branch’s aesthetic while maintaining functionality and compliance.

Challenge

The project presented several unique challenges:

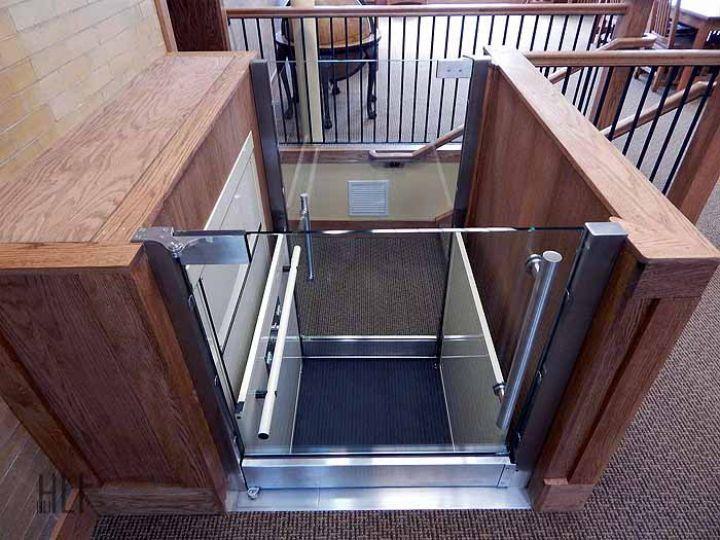

Aesthetic Requirements: The architects demanded a design with minimal visual impact, featuring as much bare-edged glass as possible to blend seamlessly into the space.

Code Compliance: Safety codes required a solid, smooth runway extending to 42” above the upper landing, limiting the extent of exposed glass.

Collaborative Coordination: Precise coordination with multiple trades, including electricians, carpenters, and stone masons, was necessary to ensure accurate installation.

Time Constraints: Construction progress had to reach a specific stage for field verification before production could begin, leaving little time for installation before the grand opening.

Design & Execution

- Custom Enclosure Design:

Incorporated patch hardware to maximize glass in the enclosure while maintaining structural integrity.

Angled the enclosure frame to follow the stair slope, creating a cohesive “stringer” effect.

Unified the design by aligning the stringer element with the top of the glass entrance shoes.

- Mechanism Integration:

Buried the lift mechanism within an adjacent wall to preserve the minimalist aesthetic.

Detailed Shop Drawings: Provided comprehensive, coordinated drawings that outlined dimensions and requirements for all related trades, ensuring a precise and efficient installation.

Field Adjustments: Released enclosure production only after construction progress allowed for field verification, successfully adapting to the compressed timeline.

Results

The completed wheelchair lift exemplifies Handi-Lift’s commitment to Accessibility with Dignity while upholding Bank of America’s standards for innovation and aesthetics:

Seamless Integration: The lift blends harmoniously with the branch’s interior design, featuring minimal hardware and extensive use of glass.

Functionality and Safety: The design meets all code requirements while delivering a quiet, reliable, and easy-to-use solution.

Timely Completion: Despite tight deadlines, the lift was installed just days before the grand opening, ready for critical clients and partners to use.

Bank of America’s flagship branch now offers a wheelchair lift that combines elegance, functionality, and accessibility, reflecting the company’s dedication to inclusivity without compromising design.

Technical Specifications

-

Lift System

Garaventa Genesis vertical platform lift with roller chain hydro drive and standby battery backup, supporting a modified live load of 500 lbs. (from the original 750 lbs.) due to additional car weight.

-

Entrance Closers

Dorma BTS-75 ADA-compliant floor closers with offset pivots ensure entrances close flush with the hoistway’s finished interior, meeting code requirements.

-

Enclosure and Glass Mounting

- Glass panels for entrances and runway walls are set inside the frames to meet code-mandated running clearance.

- Custom patch hardware and door shoes were fabricated to accommodate this design, as off-the-shelf options were incompatible.

-

Sub-Frame Design

A sub-frame around the Garaventa machine tower provides structural support for narrow glass returns and enables minimal visible support for protruding glass panels.

-

Interlocks

Folger Adams 401R deadbolt interlocks are used for their robustness with heavy glass. Positioned low to align with entrance shoes, they eliminate bulky cams or additional hardware but required modifications to the controller’s low voltage output.

-

Control Stations

Elevator-style hall stations by EPCO with raised profile buttons ensure compliance with ANSI A117.1, requiring less than 5 lbs. of pressure for operation.

-

Electrical Components

Disconnects and junction boxes are recessed behind flush access panels to maintain the lift’s clean aesthetic.

-

Car Components

- Custom stainless steel pan accommodates glass shoes and custom flooring.

- COP (car operating panel) is a 2x5x42 stainless tube with up/down and Stop/Alarm buttons on a flush, removable plate for servicing.

- Glass sides support a grab rail, designed to withstand user pull forces.

-

Mast and Finish

- Machine mast is flush with the finished wall and clad in #6 finish stainless steel, matching the architect’s low-iron glass requirement.

- Finishing work was performed by Paxton Metalcraft to meet the high aesthetic standards.

-

Installation

- Design revisions accounted for on-site conditions after concrete pouring, resulting in five iterations of coordinated shop drawings.

- Lift components were designed for quick assembly during final project stages to align with floor and wall finishes.

Location

115 West 42nd Street, New York, NY