Pembroke — 1201 Lobby Entrance

Pembroke, a real estate manager of prestigious properties around the globe, planned a large renovation project at their property 1201 and 1225 New York Avenue NW in Washington, D.C. The main entrance at 1201 New York Avenue would be upgraded and become the new accessible entrance to the atrium.

Handi-Lift collaborated with the architect on the project, Gensler, to design an accessibility solution that would complement the new dramatic entryway.

Unlock exclusive access to comprehensive solutions library and get access to the over 300+ projects

Overview

Pembroke, a global real estate manager of prestigious properties, embarked on a large renovation project at 1201 and 1225 New York Avenue NW in Washington, D.C. The focus was to upgrade the main entrance at 1201 New York Avenue, transforming it into the new accessible entryway to the atrium. Handi-Lift collaborated with Gensler, the architect for the project, to design an accessibility solution that seamlessly integrated with the dramatic new entryway.

Challenge

The renovation faced several challenges related to accessibility and design:

The elevation difference to the main lobby floor was approximately 56 inches, leaving insufficient space for a ramp or elevator shaft due to the structural beams supporting the floor.

Aesthetic concerns needed to be addressed, such as ensuring the stone and glass enclosure of the lift aligned with the stone and glass balustrade on the opposite side of the grand staircase.

Designers did not want the lift mast visible above the upper floor line, requiring innovative solutions to conceal the drive system within the design constraints.

Tight timelines and coordination among multiple trades compounded the complexity of the project.

Design & Execution

To overcome these challenges, Handi-Lift employed a customized vertical platform lift solution:

Engineering Innovations: A direct-acting hydraulic drive system with a remote pump and controller was developed. The drive system was housed in a deep pit below the lower landing, eliminating the need for a visible mast and ensuring alignment with the aesthetic requirements.

Structural Adaptations: The lift's full-support frame system was built and tested in Handi-Lift’s shop before installation, reducing on-site time. However, the single-piece frame required precise coordination with other trades to maintain exact dimensions for the finished floor-to-floor height and pit depth.

Collaborative Efforts: Despite a compressed schedule, all trades, including Handi-Lift and Lorton Stone, worked simultaneously in the same space. Double shifts were performed during the final week leading up to the grand opening to meet the aggressive timeline.

Results

The project was completed on time, with the lift seamlessly integrated into the newly renovated entryway. The innovative design met both accessibility and aesthetic goals, ensuring alignment with the architectural vision. The lift has been in daily use since the handover, providing a critical accessibility solution.

One employee, upon using the lift, described it as “a blessing,” underscoring the impact of Handi-Lift’s work. The project exemplifies Handi-Lift’s commitment to “Accessibility with Dignity” and highlights the successful collaboration between their team, Gensler, and other project partners like Lorton Stone.

Technical Specifications

-

Direct Drive

It is not often we get to install a direct drive hydraulic vertical platform lift. Usually we use a cantilevered roller chain drive or a lever hydraulic drive. The advantage to the direct drive is greater ride quality and increased capacity to handle heavy finishes.

We used a drive system by Bella Elevator, which was basically a modified residential elevator drive system. Vertical Platform Lifts must be continuous pressure controlled, so Bella modified the controller accordingly. The ride quality was enhanced but full control of speed and slow down into landings.

-

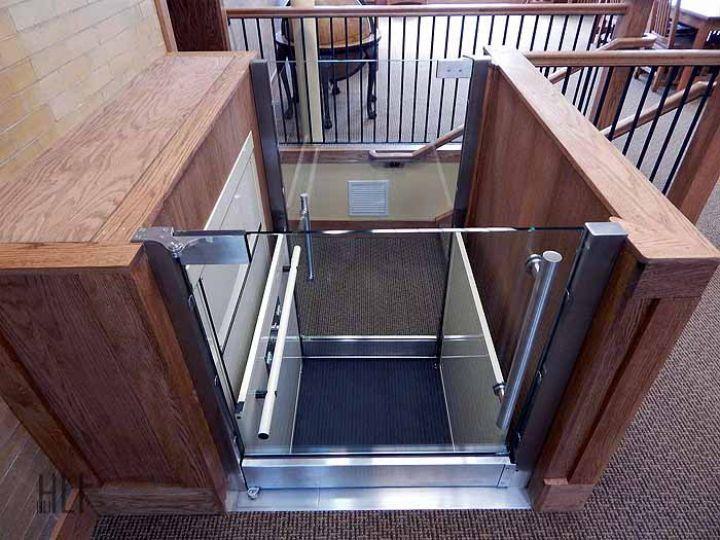

Full Frame Support and Guide System

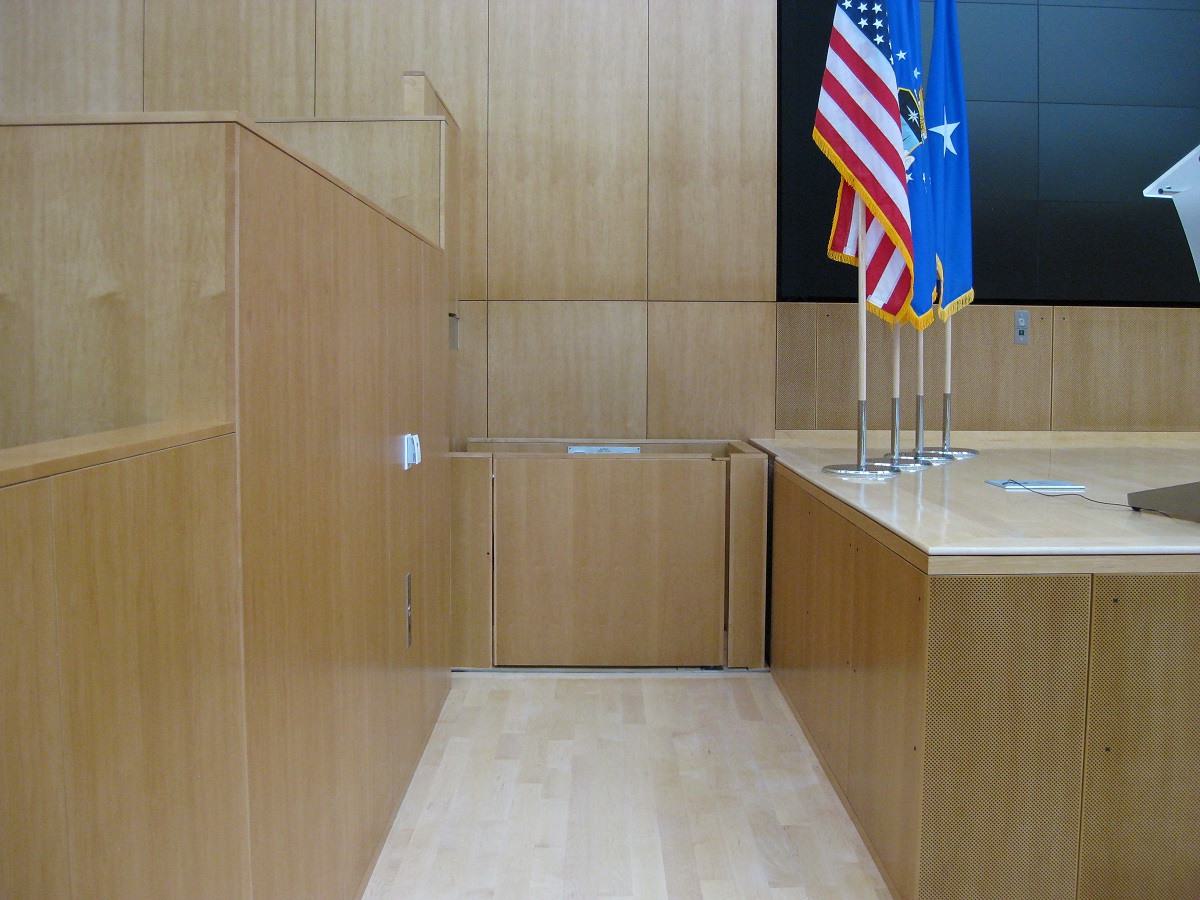

The disadvantage of this drive is the need for a lot of room below the lift for the guide system and support framework. In this case, we were able to use space beneath the lower lobby. We had 84 inches of elevation for the pit, which was plenty to fit in the piston and guide system with a thick platform, leaving a few inches to spare. None of this is visible as the lower gate was solid up to the level of the upper landing. If the gate was glass, it would need a skirt to lift out of the pit to hide the guts when the lift was in the upper landing. The only evidence of the guide system underneath are the two slots in the stainless cladding under the upper gate, which allow the two heavy arms to project through the wall and engage the roller system.

The unique system also needed to be reliable, so we wanted to be able to erect the drive in our shop for weight testing and testing the guide system and drive. If our innovation and testing were successful, the installation of the frame containing the car, piston and guide systems would be rapid. Speed of installation was critical in this project. We also pre-installed the power door operators, Dorma 400 IG (In Ground), and doors so we could make sure interlock aligned, operators could be tuned in, and door clearances were correct as per the design.

The entire unit weighed over 3,000 pounds, so transporting it by boom truck, getting it into the building, and lowering it into the pit was a challenge. The fork lift we used had just enough capacity to lift it. After the successful installation of the frame support system, we could concentrate on the finishing touches and the glass enclosure.

-

Remote Pump and Controller

This lift accesses a dramatic and rather quiet atrium in a prestigious office building. The remote pump and controller set up allows for silent operation. By not calling unnecessary attention to the user, this lift embodies one of our “Accessibility with Dignity” principles.

The original estimate of the distance from the pit to the pump room was too short. Without enough travel cable on hand, we contacted Pete Meeks from Delaware Elevator for and emergency purchase from a nearby supplier. Thanks to Monumental Supply, a miscalculation did not delay the project. We were able to get the cable we needed in less than 24 hours.

Locating the pump 100 feet from the lift presented no performance problems for this drive, once we got the air out of the hydraulic lines. Moving such a small quantity of oil traveling only 56 inches made it challenging to bleed the system.

-

Entrances

The upper gate is a bare edged glass and stainless assembly, but the lower entrance was solid up to the upper landing floor elevation. It has heavy stone cladding, then glass from the bottom of the upper landing height, and glass extending 42 inches above the upper landing due to the code-required minimum height of a vertical platform lift enclosure.

The power operators could handle the weight of the lower door without issue. We highly recommend these in the floor operators which only require 110V 20AMP power and provide an elegant solution for heavy glass, and in this case stone, entrances. A vertical platform lift where the enclosure goes only 42 inches above the upper landing has no headers on which to mount other types of power door operators. The stone cladding the lower door was a thin cut on honey comb aluminum so the increase in weight was not as dramatic. The challenge was the thickness and the need to design a custom intermediate pivot to match the lower offset pivot.

The architects wanted the stone cladding to align with the 10 inch set back from riser one on the other side of the stairs. We were not able to change the car size and miss the beam below, Lorton Stone had to do some clever cutting and mitering to return the stone back to the face of our door.

-

Platform

The platform also included a custom, vertical-column car operating panel and bare-edged glass platform sides. We used clear glass on the sides to create a lighter look next to the smoked glass of the enclosure. We made a pan to receive the stone floor and, as required, included a custom grab bar in stainless steel and attached it to the glass platform side barrier.

-

Enclosure

The enclosure was a four-sided glass box in tempered and laminated smoked glass. The glass was a special order with a long lead time. With the deadline looming, we made an emergency order of all the glass in clear ½” tempered to install temporarily if needed. Fortunately, the specified glass arrived just in time. The lobby entrance was the last phase of the project, so every trade on the job was working around us while we were installing glass, adding stress to a challenging installation.

The last element was the top rail on the glass, which matched the opposite side glass balustrade. This helps the lift blend into the space and look like it belongs. We believe “Accessibility with Dignity” means the lift should look like it was designed to fit the space, not like an afterthought.

We believe we achieved that goal thanks to an owner willing to commit to the accessibility solution, the architects’ design, and Turner Construction who gave us the opportunity to work on this prestigious Pembroke project.

Location

1201 New York Avenue Northwest, Washington D.C., DC 20005, USA